- DANFOSS

- Renewable Energy

- Totally Integrated Automation System

- Medium and low voltage inverter system

- Conveyor Weighing System

- Automatic transfer switch system - ATS

- Motor control center system - MCC

- Distributed Control System - DCS

- PLC - SCADA control system

- TPS control system

- Online coal analyzer and monitor system

- MV and LV soft start system

- UPS system

- MDB & DB distribution cabinets, power supply cabinets

- MARECHAL - TECHNOR

- BORRI

- FLENDER

- DURAG

- SOLCON

- SIEMENS

- METSO OUTOTEC

- Technical service

Product Categories

|

Liên hệ:

|

|

|

Hot line: 0902 195 055 |

|

|

VP Hà Nội : 024 6269 7755

VP HCM : 028 3517 8949

|

Supplier

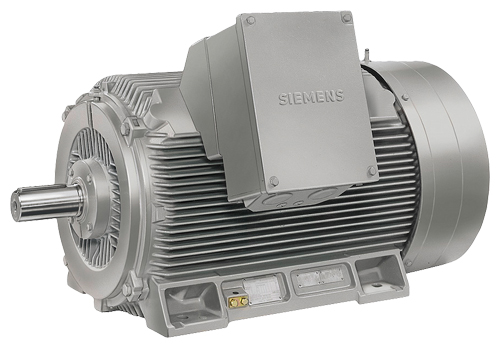

SIMOTICS TN Series N-compact Non-Standard Motors

SIMOTICS TN Series N-compact Non-Standard Motors

SIMOTICS TN Series N-compact: Series 1LA8, 1PQ8, 1LL8

The three-phase motor series SIMOTICS TN Series N-compact covers outputs up to 1250 kW (at 50 Hz) in the non-standard range. A number of technical features provide this motor series with its ruggedness and long service life and ensure the highest level of availability, for example, motor protection with PTC thermistors with 6 embedded temperature sensors for alarm and tripping is standard.

SIMOTICS TN Series N-compact motors are also characterized by their high output for small frame size. The consequence of this is an extremely compact design that can be used to save space in a number of industrial applications.

SIMOTICS TN Series N-compact motors are not only optimized in terms of their construction, but also in terms of their efficiency, so they also contribute towards lower energy consumption.

Apart from mains-fed operation, the SIMOTICS TN Series N-compact motors are also specially designed for converter-fed operation, for example, insulated bearings are used at the non-drive-end NDE for converter-fed operation as standard to prevent damage being caused as a result of bearing currents. In combination with frequency converters from the SINAMICS and SIMOVERT MASTERDRIVES product series, they build up perfectly interacting drive systems for variable-speed drive applications.

Versions in the SIMOTICS TN N-compact series

Series 1LA8

The motors are asynchronous squirrel-cage motors with compact dimensions in fin-cooled design. They are designed for direct connection to the three-phase supply and for converterfed operation.

|

1LA8 for mains-fed operation |

1LA8 for converter-fed operation |

|

|

Series 1PQ8

The motors are asynchronous squirrel-cage motors with compact dimensions in fin-cooled design with forced ventilation. As these motors are forced-ventilated, no derating or only relatively minor derating (depending on their speed range) is required for operation at constant load torque and with wide speed ranges. The motors are designed for converter-fed operation with the SINAMICS and SIMOVERT MASTERDRIVES drive system.

|

1PQ8 for converter-fed operation |

|

|---|---|

|

|

Series 1LL8

The motors of series 1LL8 are asynchronous squirrel-cage motors with compact dimensions in an open fin-cooled design with self-cooling. They are similar in construction to 1LA8 motors. IP23 degree of protection is achieved by opening the internal cooling circuit which enables it to be supplied with external cooling air. This can increase the performance by up to 25 % as compared to the 1LA8. They are designed for direct connection to the three-phase supply and for converter-fed operation.

Motors of the 1LL8 type series are intended for installation indoors. They must not be subjected to humid, salty or corrosive atmospheres.

|

1LL8 for mains-fed operation |

1LL8 for converter-fed operation |

|---|---|

|

|

Versions with special insulation for > 500 V and operation without an output filter on the frequency converter are only available on request.

Standardline

4-pole 1LA8 motors up to 500 kW are available with a reduced range of options as the Standardline.

Benefits to the customer:

- Much shorter delivery time

- Can be configured with a variety of options, retaining a high degree of flexibility.

Applications

Standardline low-voltage motors are optimized for applications in pump, fan and compressor drives. The low-voltage motors are specially constructed for use in complete, coordinated drive systems comprising the motor and a SINAMICS G150 frequency converter.

Standardline motors can be ordered using order code B20.

Scope of the Standardline

- 4-pole version

- Power range 250 to 500 kW

- Types 1LA8315, 1LA8317, 1LA8353, 1LA8355 and 1LA8357

- Type of construction code 0 (IM B3)

- For mains-fed operation: Voltage code 6 (400 VΔ/690 VY) or 5 (500 VΔ)

- For converter-fed operation: Voltage code 4 (400 VΔ), 8 (400 VΔ/690 VY) or 5 (500 VΔ)

- Can be ordered for converter-fed operation, but not in the 690 V version

- Possible order codes: A23, A61, A72, G50, H70, H73, K09, K10, K45, K46, K57, K83, K84, K85, L00, L97, M58 (frame size 315 only), M88 and Y53

Benefits

Non-standard motors from Siemens offer the user numerous advantages:

- The optimized efficiency results in lower operating costs.

- The high output/size ratio ensures low space requirements combined with low weight.

- The cast-iron housing and bearing plates are extremely rigid and rugged and can therefore be subjected to considerable stress and have excellent vibration damping properties and are resistant to corrosion.

- The bearings are designed for maximum reliability, which results in good vibration characteristics, a long service life and low maintenance costs.

- The DURIGNIT IR 2000 insulation system with VPI or current-UV impregnation results in high reliability, a long service life and high resistance to stress, for example, during starting or under overload conditions.

- Due to the low noise emission level, the stringent requirements of worker protection are fulfilled without the need for additional measures.

Application

Thanks to the many options, the motor series SIMOTICS N-compact covers applications in a wide range of different sectors: Chemicals, paper, water/waste water, steel and shipbuilding are just a few examples. The available types of construction are IM B3, IM B35 and IM V1 according to DIN EN 60034-7. The degree of protection is IP55 as standard, but IP23 for motor series 1LL8.

The 1PQ8 motors are specially designed for variable-speed applications with constant torque. The mounted separately driven fan provides a constantly high cooling air flow at any speed. These motors can therefore be continuously operated at low speed and high torque simultaneously.

The low-voltage motor series SIMOTICS N-compact is also available in a through-ventilated version to IP23 degree of protection. This 1LL8 motor series boasts an output 25 % higher than that of the closed 1LA8 motor series for the same frame size.

The 1LL8 motor is therefore useful for applications in which a closed 1LA8 motor is not essential and when the ambient conditions permit the use of a through-ventilated machine (IC 01 cooling method, IP23 degree of protection). Motors of the 1LL8 type series are only intended for installation indoors.

They must not be subjected to humid, salty or corrosive atmospheres.

Sản phẩm liên quan

SIMOTICS TN Series N-compact Non-Standard Motors

SIMOTICS TN Series N-compact: Series 1LA8, 1PQ8, 1LL8

(Tiếng Việt) SIMOTICS TN Series H-compact PLUS

SIMOTICS TN Series H-compact

Maximum power - minimum size – especially for converter operation

SIMOTICS TN Series H-compact

SIMOTICS TN Series H-compact

Maximum power - minimum size – especially for converter operation

- DANFOSS

- Renewable Energy

- Totally Integrated Automation System

- Medium and low voltage inverter system

- Conveyor Weighing System

- Automatic transfer switch system - ATS

- Motor control center system - MCC

- Distributed Control System - DCS

- PLC - SCADA control system

- TPS control system

- Online coal analyzer and monitor system

- MV and LV soft start system

- UPS system

- MDB & DB distribution cabinets, power supply cabinets

- MARECHAL - TECHNOR

- BORRI

- FLENDER

- DURAG

- SOLCON

- SIEMENS

- METSO OUTOTEC

- Technical service

Product Categories

|

Liên hệ:

|

|

|

Hot line: 0902 195 055 |

|

|

VP Hà Nội : 024 6269 7755

VP HCM : 028 3517 8949

|