- NVCHARGE SOLUTION FOR ELECTRIC VEHICLES

- DANFOSS

- RENEWABLE ENERGY

- INTERGRATED SOLUTIONS

- Medium and low voltage inverter system

- Conveyor Weighing System

- Automatic transfer switch system - ATS

- Motor control center system - MCC

- Distributed Control System - DCS

- PLC - SCADA control system

- TPS control system

- Online coal analyzer and monitor system

- MV and LV soft start system

- UPS system

- MDB & DB distribution cabinets, power supply cabinets

- MARECHAL - TECHNOR

- BORRI

- FLENDER

- DURAG

- SOLCON

- SIEMENS

- METSO OUTOTEC

- TECHNICAL SERVICE

Product Categories

|

Liên hệ:

|

|

|

Hot line: 0902 195 055 |

|

|

VP Hà Nội : 024 6269 7755

VP HCM : 028 3517 8949

|

Supplier

ARPEX ARS-6

Coupling can be designed for potentially explosive environments.

Benefits

ARPEX couplings of the ARS-6 series are outstanding for their versatility. Most standard components are available from stock, resulting in short delivery times. Their use in potentially explosive environments in accordance with Directive 94/9/EC is possible.

Application

ARPEX couplings of the ARS-6 series are a versatile coupling solution which thanks to standard modular components can be used for most drive requirements at a low to medium speed. Torques of between 170 and 106000 Nm can be transmitted at a permitted angular misalignment of 0.7°. The open flange form is regarded as very easy to fit and has easily accessible screw connection points. On most types, the intermediate spacer can be radially fitted without moving the connected units.

Main areas of application for the ARS-6 series:

- Paper-making machines

- Printing machines

- Compressors

- Pumps

- Fans and blowers

- Film and foil machines

- Generators

- Presses

- Metalworking machines

- Conveyors

- Crane systems

- Textile machines

- Plastics processing machines

- Centrifuges

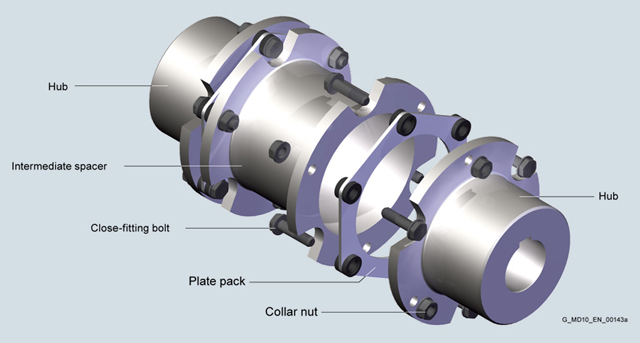

Design

The classic design of an ARPEX couplings of the ARS-6 series is shown in the following illustration. The plate packs are bolted alternately between the flanges of the coupling hubs and the intermediate spacer. Up to size 280-6 close-fitting bolts and from size 305-6 conical screw connections are used for fastening. A large number of intermediate spacer and shafts, hubs and flanges can be combined and thus cover a large number of possible drive requirements.

Design of an ARPEX coupling, ARS-6 series, type NEN

Variants of the ARPEX coupling, ARS-6 series

|

Types |

|

|---|---|

|

NEN, BEN, BEB |

Variant with standard intermediate spacer, many sizes available from stock |

|

NON, BON |

Variant with shortest intermediate spacer |

|

NUN, BUN, BUB |

Variant with split intermediate spacer |

|

NHN |

Variant with intermediate spacer for customer-specific shaft distance |

|

NZN |

Variant with reinforced intermediate spacer |

|

NWN |

Variant with intermediate shaft |

All coupling types can be very easily combined with further standard components in the ARPEX modular system. Jumbo hubs are used to permit larger maximum bores.

Clamping hubs transmit torque by friction without the use of parallel keys. F, D and C flanges offer many different possibilities for flange connection.

The coupling parts of the ARPEX ARS-6 series are machined on all sides. Exceptions are H and Z spacers and intermediate shafts. The spacers are delivered with unmachined, primed spacer tube.

Higher torques and maximum speeds with similar coupling outer diameters DA can be achieved with the ARPEX ARC-8/-10 series.

Further application-specific coupling types are available in selection module x.CAT at www.flender.com. Dimension sheets and further information are available on request.

Power ratings

|

Size |

Rated torque |

Maximum torque |

Overload torque |

Fatigue torque |

Maximum speed |

Maximum permitted shaft misalignment |

Torsional stiffness |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

DA |

TKN |

TKmax |

TKOL |

TKW |

nKmax |

±ΔKa |

±ΔKw |

±ΔKr |

CTdyn |

|||||||

|

NHN |

NEN/BEN |

NON |

NEN |

NUN |

NON |

NHN |

NZN |

NWN |

||||||||

|

Nm |

Nm |

Nm |

Nm |

rpm |

mm |

mm |

mm |

mm |

MNm/rad |

MNm/rad |

MNm/rad |

MNm/rad |

MNm/rad |

MNm/rad |

||

|

78-6 |

170 |

320 |

510 |

85 |

13400 |

1.10 |

0.7° |

12.1 |

0.57 |

0.53 |

0.05 |

0.04 |

0.05 |

0.012 |

0.032 |

0.05 |

|

105-6 |

270 |

510 |

810 |

135 |

10000 |

1.80 |

12.1 |

0.88 |

0.53 |

0.09 |

0.09 |

0.09 |

0.024 |

0.070 |

0.09 |

|

|

125-6 |

490 |

930 |

1470 |

245 |

8400 |

2.02 |

12.1 |

1.04 |

0.68 |

0.17 |

0.17 |

0.18 |

0.043 |

0.141 |

0.19 |

|

|

140-6 |

700 |

1330 |

2100 |

350 |

7500 |

2.40 |

12.1 |

1.28 |

0.72 |

0.22 |

0.22 |

0.24 |

0.066 |

0.203 |

0.25 |

|

|

165-6 |

1250 |

2370 |

3750 |

625 |

6350 |

2.74 |

12.0 |

1.49 |

0.84 |

0.33 |

0.34 |

0.36 |

0.114 |

0.317 |

0.39 |

|

|

175-6 |

2000 |

3800 |

6000 |

1000 |

6000 |

2.86 |

12.0 |

1.55 |

0.98 |

0.48 |

0.50 |

0.52 |

0.196 |

0.443 |

0.57 |

|

|

195-6 |

3000 |

5700 |

9000 |

1500 |

5350 |

3.06 |

12.0 |

1.55 |

0.98 |

0.67 |

0.69 |

0.73 |

0.302 |

0.614 |

0.79 |

|

|

210-6 |

4400 |

8300 |

13200 |

2200 |

5000 |

3.14 |

12.0 |

1.77 |

1.10 |

0.77 |

0.78 |

0.82 |

0.352 |

0.669 |

0.88 |

|

|

240-6 |

5700 |

10800 |

17100 |

2850 |

4350 |

3.70 |

12.0 |

1.93 |

1.20 |

1.24 |

1.26 |

1.32 |

0.568 |

1.04 |

1.40 |

|

|

255-6 |

7600 |

14400 |

22800 |

3800 |

4100 |

3.84 |

11.9 |

2.09 |

1.50 |

1.39 |

1.42 |

1.46 |

0.697 |

1.22 |

1.57 |

|

|

280-6 |

10000 |

19000 |

30000 |

4600 |

3750 |

4.18 |

11.9 |

2.53 |

1.53 |

1.55 |

1.57 |

1.65 |

0.881 |

1.42 |

1.73 |

|

|

305-6 |

12000 |

21000 |

36000 |

5000 |

3400 |

4.46 |

11.9 |

2.72 |

1.80 |

2.83 |

2.87 |

3.05 |

1.51 |

2.71 |

3.32 |

|

|

335-6 |

18000 |

32000 |

54000 |

7500 |

3100 |

4.84 |

11.9 |

2.88 |

1.89 |

3.85 |

3.92 |

4.14 |

2.11 |

3.62 |

4.49 |

|

|

372-6 |

24000 |

43000 |

72000 |

10000 |

2800 |

4.98 |

11.8 |

3.03 |

2.16 |

5.72 |

5.84 |

6.12 |

3.14 |

– |

6.75 |

|

|

407-6 |

34000 |

61000 |

102000 |

14000 |

2550 |

5.50 |

11.8 |

3.31 |

2.26 |

7.25 |

7.42 |

7.79 |

5.06 |

– |

8.51 |

|

|

442-6 |

43000 |

77000 |

129000 |

18000 |

2350 |

6.02 |

11.8 |

3.59 |

2.48 |

10.0 |

10.2 |

10.8 |

7.42 |

– |

11.9 |

|

|

487-6 |

55000 |

99000 |

165000 |

23000 |

2150 |

6.80 |

11.7 |

4.09 |

2.64 |

11.7 |

11.9 |

12.7 |

9.25 |

– |

13.6 |

|

|

522-6 |

69000 |

124000 |

207000 |

29000 |

2000 |

7.34 |

11.7 |

4.35 |

2.86 |

14.0 |

14.3 |

15.1 |

11.4 |

– |

16.2 |

|

|

572-6 |

92000 |

166000 |

276000 |

38000 |

1800 |

7.86 |

11.6 |

4.87 |

3.02 |

17.9 |

18.3 |

19.4 |

15.2 |

– |

20.7 |

|

|

602-6 |

106000 |

191000 |

318000 |

44000 |

1700 |

8.24 |

11.6 |

5.13 |

3.24 |

21.1 |

21.7 |

22.9 |

18.2 |

– |

24.5 |

|

The permitted shaft misalignments ΔKa, ΔKr and ΔKw are maximum values and must not occur at the same time (see following table).

The permitted shaft misalignment ΔKr for types NHN, NZN and NWN applies to a coupling with shaft distance S = 1000 mm.

For other shaft distances the permitted radial misalignment can be determined with the following formula:

ΔKr = (S – S1) · tan (ΔKw).

The shaft distance S is shown on the table for the type.

TKmax permitted only five times per hour.

The values for torsional stiffness apply to the complete coupling. In the case of types NHN and NZN to a coupling with shaft distance S = 1000 mm. In the case of type NWN, the torsional stiffness applies to a coupling without intermediate or torsion shaft. The torsional stiffness of the plate packs applies to the rated coupling torque TKN. To determine the torsional stiffness for a specific operating point, e.g. for calculating torsional vibration, the manufacturer must be consulted.

Permitted shaft misalignments

|

Size |

Permitted angular misalignment ±ΔKw |

|||||||

|---|---|---|---|---|---|---|---|---|

|

0.0° |

0.1° |

0.2° |

0.3° |

0.4° |

0.5° |

0.6° |

0.7° |

|

|

DA |

Permitted axial misalignment ±ΔKa in mm |

|||||||

|

78-6 |

1.10 |

0.94 |

0.79 |

0.63 |

0.47 |

0.31 |

0.16 |

0.00 |

|

105-6 |

1.80 |

1.54 |

1.29 |

1.03 |

0.77 |

0.51 |

0.26 |

0.00 |

|

125-6 |

2.02 |

1.73 |

1.44 |

1.15 |

0.87 |

0.58 |

0.29 |

0.00 |

|

140-6 |

2.40 |

2.06 |

1.71 |

1.37 |

1.03 |

0.69 |

0.34 |

0.00 |

|

165-6 |

2.74 |

2.35 |

1.96 |

1.57 |

1.17 |

0.78 |

0.39 |

0.00 |

|

175-6 |

2.86 |

2.45 |

2.04 |

1.63 |

1.23 |

0.82 |

0.41 |

0.00 |

|

195-6 |

3.06 |

2.62 |

2.19 |

1.75 |

1.31 |

0.87 |

0.44 |

0.00 |

|

210-6 |

3.14 |

2.69 |

2.24 |

1.79 |

1.35 |

0.90 |

0.45 |

0.00 |

|

240-6 |

3.70 |

3.17 |

2.64 |

2.11 |

1.59 |

1.06 |

0.53 |

0.00 |

|

255-6 |

3.84 |

3.29 |

2.74 |

2.19 |

1.65 |

1.10 |

0.55 |

0.00 |

|

280-6 |

4.18 |

3.58 |

2.99 |

2.39 |

1.79 |

1.19 |

0.60 |

0.00 |

|

305-6 |

4.46 |

3.82 |

3.19 |

2.55 |

1.91 |

1.27 |

0.64 |

0.00 |

|

335-6 |

4.84 |

4.15 |

3.46 |

2.77 |

2.07 |

1.38 |

0.69 |

0.00 |

|

372-6 |

4.98 |

4.27 |

3.56 |

2.85 |

2.13 |

1.42 |

0.71 |

0.00 |

|

407-6 |

5.50 |

4.71 |

3.93 |

3.14 |

2.36 |

1.57 |

0.79 |

0.00 |

|

442-6 |

6.02 |

5.16 |

4.30 |

3.44 |

2.58 |

1.72 |

0.86 |

0.00 |

|

487-6 |

6.80 |

5.83 |

4.86 |

3.89 |

2.91 |

1.94 |

0.97 |

0.00 |

|

522-6 |

7.34 |

6.29 |

5.24 |

4.19 |

3.15 |

2.10 |

1.05 |

0.00 |

|

572-6 |

7.86 |

6.74 |

5.61 |

4.49 |

3.37 |

2.25 |

1.12 |

0.00 |

|

602-6 |

8.24 |

7.06 |

5.89 |

4.71 |

3.53 |

2.35 |

1.18 |

0.00 |

Sản phẩm liên quan

ARPEX ARS-6

Khớp nối thép ARPEX®, thuộc loại khớp nối thép dòng ARS-6 không phải bảo trì được sử dụng rộng rãi cho các ứng dụng có tốc độ từ thấp đến trung bình với độ sai lệch góc cho phép lên tới 0.7°.

ARPEX ARS – 6 COMPOSITE

Khớp nối thép ARPEX®, thuộc series ARS-6 COMPOSITE kết hợp khớp thép không phải bảo trì với công nghệ Composite mới

ARPEX ARP – 6

Khớp nối thép ARPEX® dùng cho truyền động bơm, khớp nối thép không phải bảo trì ARP-6 được ứng dụng tối đa cho truyền động bơm, đặc biệt cho các loại bơm ly tâm với sai lệch góc cho phép lên tới 0.7°. Đáp ứng các điều kiện API 610. Các tuỳ chọn cho thiết kế kiểu API 671 cũng được hỗ trợ

ARPEX ARM – 4

Khớp nối thép ARPEX®, thuộc dòng khớp nối thép nhỏ ARM-4 không phải bảo trì được dùng cho các truyền động có mômen rất thấp và sai lệch góc cho phép lên tới 1°.

ARPEX ARF – 6

Khớp nối thép ARPEX® là loại khớp nối thép không phải bảo trì thuộc seri ARF-6 được dùng trong các ứng dụng có momen từ thấp đến trung bình nhưng có khoảng cách trục cực kỳ ngắn và sai lệch góc cho phép lên tới 0.7°.

ARPEX ARC-8/10

Khớp nối thép ARPEX®, ARC-8/10 là loại khớp thép không phải bảo trì có mômen lớn và tốc độ cao với độ sai lệch góc cho phép lên tới 0.3o.

ARPEX ART-6/8/10

Khớp nối thép ARPEX®, dòng khớp nối tốc độ cao ART-6/8/10 ứng dụng trong hệ truyền động rất tinh vi trong lĩnh vực cấp nguồn, trong công nghiệp hoá học dầu khí và trong hàng hải

- NVCHARGE SOLUTION FOR ELECTRIC VEHICLES

- DANFOSS

- RENEWABLE ENERGY

- INTERGRATED SOLUTIONS

- Medium and low voltage inverter system

- Conveyor Weighing System

- Automatic transfer switch system - ATS

- Motor control center system - MCC

- Distributed Control System - DCS

- PLC - SCADA control system

- TPS control system

- Online coal analyzer and monitor system

- MV and LV soft start system

- UPS system

- MDB & DB distribution cabinets, power supply cabinets

- MARECHAL - TECHNOR

- BORRI

- FLENDER

- DURAG

- SOLCON

- SIEMENS

- METSO OUTOTEC

- TECHNICAL SERVICE

Product Categories

|

Liên hệ:

|

|

|

Hot line: 0902 195 055 |

|

|

VP Hà Nội : 024 6269 7755

VP HCM : 028 3517 8949

|